Maintenance and repair of sewers systems remains a major challenge in the ever-changing construction landscape. The traditional methods of replacing damaged pipes with extensive excavations are not only disruptive to daily life, but they also have a high environmental and financial price. Sewer pipe lining is a trenchless technique that has been praised for its efficiency and minimal disturbance. This article offers valuable insight for both contractors and consumers on sewer pipe lining.

What is Sewer Pipe Lining ?

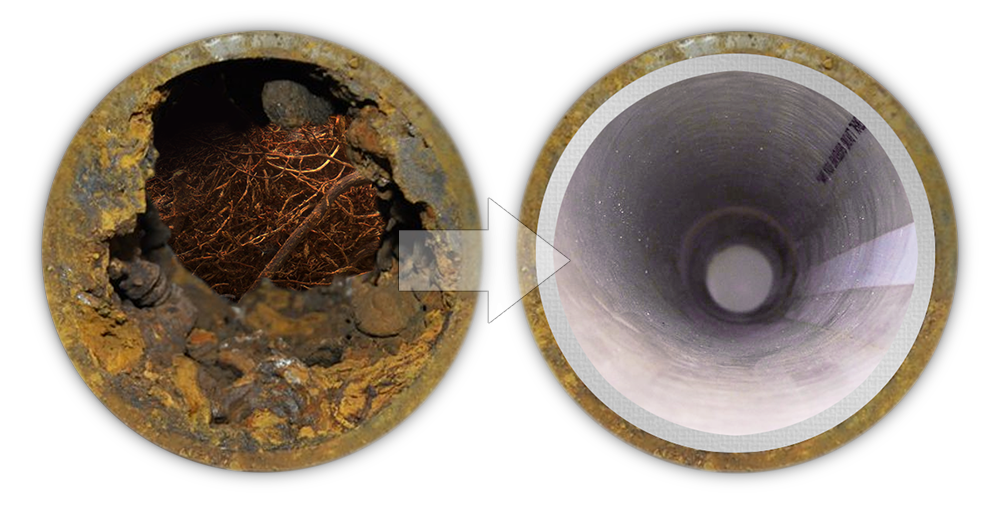

Sewer pipe lining is also known as cured in place pipe (CIPP). It is a trenchless method of rehabilitation that can be used to repair sewer pipes without extensive excavation. The technique involves inserting an elastic, resin-saturated lining into the damaged pipe. This liner is then stretched to fit snugly along the interior walls of the pipe. The resin can be cured by heat, UV light or ambient temperature. This creates a “pipe inside a pipe”, which restores structural integrity and flow capability of the original pipe.

Benefits of Sewer Pipe Lining

- Reduced Disruption – One of the main benefits of sewer pipe linings is that they cause minimal disruption. This trenchless method is more environmentally friendly than traditional methods because it does not require extensive digging. It also preserves landscaping, driveways and infrastructure.

- Sewer pipe lining can be more cost effective than replacing pipes, particularly when you consider the indirect costs of excavation, like landscape restoration and road closings.

- Longer Lifespan: Materials used for pipe lining are designed with the ability to withstand mechanical, chemical, and thermal stresses. This allows them to extend the life of an existing sewer system.

- Environmental Benefits: By reducing the amount of excavation required, sewer pipe lining is a more environmentally friendly alternative to pipe replacement and repair.

The Disadvantages Of Sewer Pipe Lining

- The lining of sewer pipes is not a solution for every type of damage. This method may not work for pipes that are severely collapsed or have extensive joint separation.

- This process reduces the diameter of the pipe by a small amount. This reduction is usually negligible but can be considered in pipes that have flow capacity problems.

- Chemical Sensitivity – The resins that are used to line the vehicle can be sensitive towards certain chemicals. This could affect the durability of repairs in particular environments.

When can sewer pipe lining be used?

The sewer pipe lining can be used to repair leaks, cracks and root intrusions as well as minor collapses of residential and commercial sewer pipes. The lining can be used on pipes made of clay, cast iron or PVC. It is not suitable for pipes which are completely collapsed or severely misaligned. It is important to conduct a thorough inspection using video cameras in order to determine whether sewer pipe lining will work for a particular situation.

When can’t sewer pipe lining be used?

In some cases, sewer pipe lining is not the best option.

- The pipe will not be able to be lined if it has completely collapsed. There is no support structure for the liner.

- Significant Misalignment – While minor misalignments may be tolerated, serious cases where pipes are shifted drastically require excavation and pipe replacement.

- Certain materials or conditions of pipe may not be compatible with the resin types used in the lining procedure.

Sewer Pipe Lining Process

There are several steps involved in the process of sewer pipe lining.

- Inspection: Video camera inspections are performed to determine the condition of the pipes and identify any problems.

- Cleaning: The pipe will be thoroughly cleaned with hydro jets or mechanical methods in order to ensure that the liner adheres properly.

- Lining: A resin-saturated lining is inserted in the pipe through an existing access hole.

- Curing: After the resin has cured, it forms a durable, hard lining which adheres to pipe interiors.

- Final Inspection: The final inspection of the camera installation verifies its quality.

How to Choose a Contractor

Consider the following when choosing a contractor to line sewer pipes:

- Experience: Choose a company that has extensive experience with trenchless technologies.

- Check references and ask for them from previous clients.

- Warranty: Make sure the contractor provides a guarantee on their services, which shows confidence in them.

Sewer pipe lining is a durable, cost-effective and environmentally friendly option to the traditional methods of pipe replacement. Although it is not appropriate for all situations, the benefits are significant in terms of cost savings, reduced disruption and increased pipe life. The decision to use sewer pipe lining must be made after a thorough evaluation of the pipe condition and its suitability for the damage or degradation that is present.

Contractors and consumers should engage in detailed conversations with professionals who are experienced in evaluating the sewer system. This evaluation should cover the following: the cost estimate, the expected lifetime of the lining and any limitations or risks that may be associated with this procedure.

Both parties must also be aware of the requirements for maintaining a pipe that has been lined. Regular cleaning and inspections are essential to ensure the durability of the repair. The resins used to line the pipe are resistant to most common causes of damage but are not indestructible. Proactive maintenance can extend the life of the repair.

The environmental considerations also play a significant role in the decision making process. Sewer pipe lining is trenchless, which minimizes its impact on the surrounding environment, protecting landscapes, structures and local eco-systems. This makes it a good option for projects that prioritize environmental conservation.

Sewer pipe lining offers a sophisticated solution to many challenges that are associated with maintaining or repairing sewer infrastructure. Sewer pipe lining is a popular choice for new construction projects and rehabilitation. It is important to understand its limitations, costs, and applications. Contractors and consumers who work closely with professionals can make informed choices that will ensure the integrity of their sewer system for many years. Sewer pipe lining is a viable, cost-effective, and environmentally friendly alternative to traditional pipe replacement and repair methods.