CIPP can last up to 60 years with proper maintenance. , without being cured only has a lifespan of 10 to 15 years . The liner could slip and become unstable.

This can extend the life of an existing system. It can increase the lifespan of a system for more than 100 years.

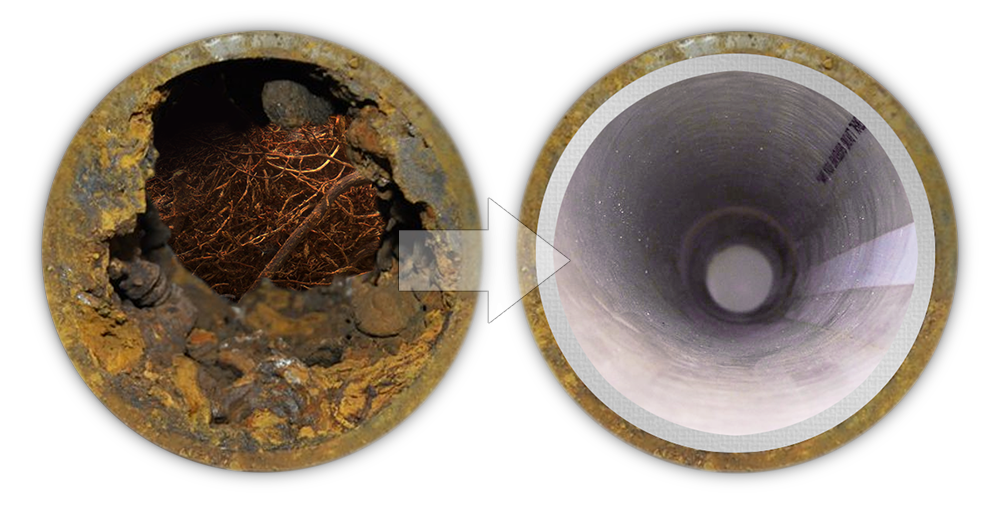

The term CIPP liner is used to describe pipe linings that have been curing in place. This is a method of trenchless restoration to restore existing pipelines. If properly maintained, it can last up to 50 years. This procedure can be used to repair pipes damaged by leaks or cracks. It also helps prevent encroaching root growth. This procedure can extend the life of an existing pipe system, while potentially saving building structures and causing minimal property damage.

How is CIPP lining made?

To save a pipe that is withering, the pipe must first be repaired using fabric liners and liquid resin. The liners consist of a resin mixture that consists of an epoxy base and hardeners. The textile liner can be inserted into the pipe using air pressure. At this point, the resin has been applied to the outside of the pipe.

The calibrating tubes will then be inserted into the textile liners, and they are cured using steam or hot water. The curing chemicals activate the resin in this step and cause it to harden, forming a smooth, corrosion resistant pipe wall.

Material Composition

Material used for trenchless pipes installation is unique. This lining is composed of a resin containing polyesters, fiberglass, or other impervious material. Once triggered, it produces a new liner inside the existing pipe. This seamless pipelining is a revolutionary product that eliminates the use of connectors at bends and in other places. Your skilled installers will use water, steam, or UV light to cure the material they are using.

Check that your team of qualified professionals have done similar work before. Ask if they can pass any inspections.

Professional Restore Pipe Systems Lining Installation Process

The Process of Restore Pipelining requires an initial project inspection. You’ll want to plan because not every installation will be the same. To place the resin into the damaged section of the pipe, pinpoint accuracy is required. The new treatment, if done correctly, should seal the pipes internally, rejuvenating them to a lifetime of use.

Double-check to ensure that all unique equipment, assessments, or correct installations will pass any local building inspections. You will also get the best warranty for your peace-of-mind.

M & B Services offers the best CIPPs in MInnesota! Call us for more information.