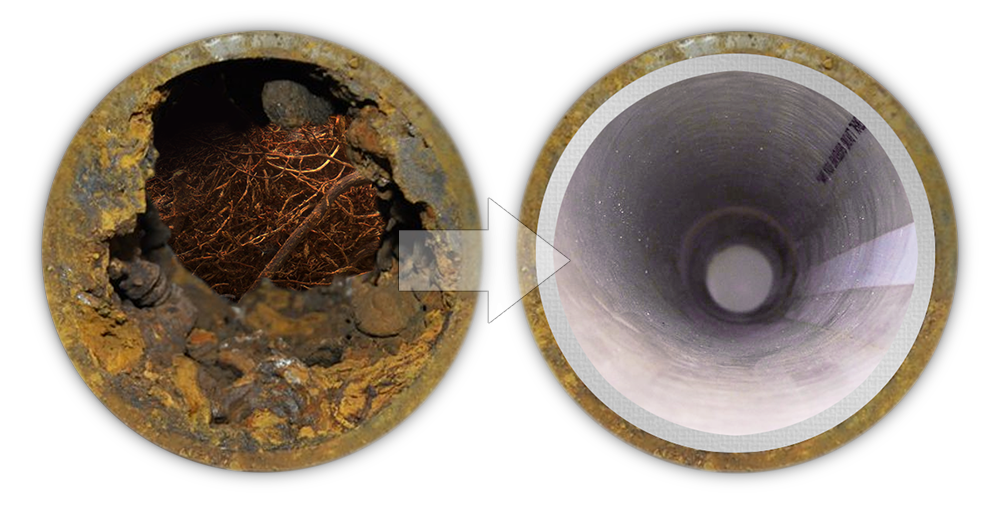

Cured-in-place pipe lining is a method for trenchless pipe repair and restoration. This is used to protect the pipes after they have been damaged by cracks, leaks, roots intruding into them, or rust. This process can increase the life expectancy of a pipe system by up to 100 years, while protecting the structure and causing minimal to no property damage.

CIPP Lining:

Customers can rest assured that their property above ground won’t be damaged by a pipe relining company that doesn’t require digging. All the work for pipe lining will take place below ground. The video pipe inspection technology will be used by the CIPP lining contractor to locate the damage. Next, the plan will be drawn out to repair the pipe.

Top 10 Advantages

Less expensive than traditional pipe repair

Because there are fewer workers, equipment and time required for each project, CIPP lining is less expensive than traditional digging for pipeline repair.

Pipes can last 50+ years

The epoxy used in the new lining is extremely strong. It is resistant to rotting, and corrosion. They can last for up to 100 years if they are well maintained.

Resistant To Root Intrusion

The epoxy is strong and thick so roots can’t penetrate it. This is a huge advantage for those areas that have to deal with this issue all the time. They will have a longer life span for their pipes.

One Section at a Time

You can repair a section of pipe that is small enough to cause damage without affecting the rest of your system.

You don’t need to redo the entire pipe system to fix

Traditional methods are not safe for repairing small sections of pipes without affecting the whole system. CIPP does not cause any damage to the pipes surrounding them or the land.

Higher Flow Efficiency

The CIPP liner has a smooth surface and is durable. It allows liquids and small solids to flow through pipes easily. There is nothing for debris to stick onto or slow down.

Completely Trenchless

You can do CIPP lining anywhere. It does not require any digging or disrupt the surrounding environment.

Minimum Equipment and Workers Required

A large number of workers are not required for the pipe repair job. There is no need for large equipment. This job is easily completed in two workers, and it can be done very quickly.

Less Noisy Digging Options

It takes up very little space to store the equipment required for CIPP lining. The equipment is also required by 3 machines. There are only a few workers on these sites so there isn’t much noise.

Very Quick Processing

The CIPP process takes approximately 2-2.5 hours. It all depends on the scope of the project and its requirements. CIPP is often used to quickly repair pipe systems.

How long will the CIPP lining take?

The pipe system is coated with epoxy resin. This provides a waterproof, corrosion-resistant, wear-resistant, non-corrosive, and damp-proof lining. The lining protects the system and makes it stronger to last for many decades. A CIPP lining can be expected to last for up to 100 year. The lining can also protect against root intrusion, cracks and leaks as well as other damages caused by underground utilities.

What is the cost of CIPP lining?

Each individual will determine the cost of pipe linings that are cured in situ. These are some of the determining factors:

- The pipes themselves

- How often does the pipe need to be cleaned?

- It is difficult to get to the pipe

It is, however, more affordable than traditional methods of pipe repair. Get a quote for your pipe lining project from M & B Services.