CIPP (Cured-in-Place-Pipe Lining) is a trenchless method for installing sewer pipes. The process requires little digging and takes less time than other methods of sewer repair. These are suitable for repairing both short and long pipelines that do not require upsizing.

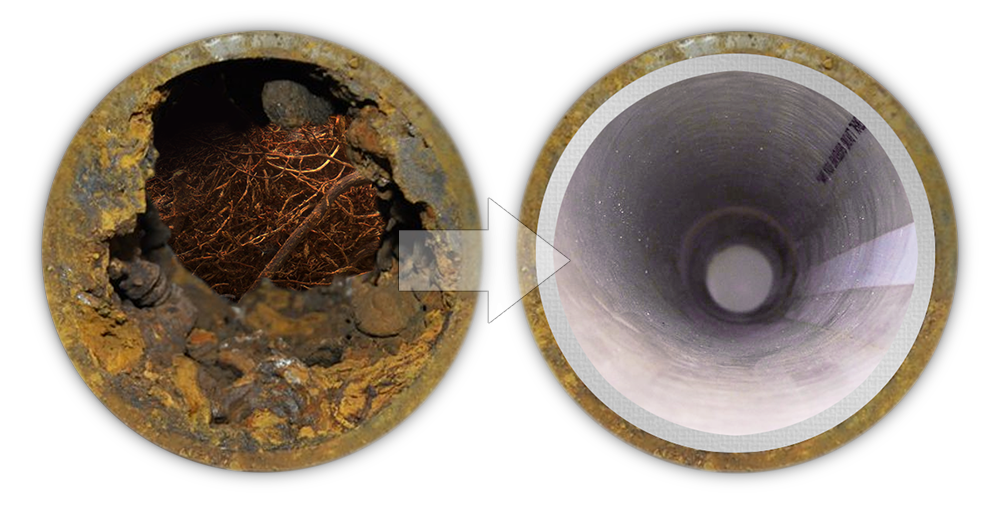

In CIPP, a flexible liner is inserted inside an existing pipe, inflated, and then exposed to heat or ultraviolet light to dry and harden the liner. Liners create a smooth surface inside existing pipes, restoring them to near-new condition.

The work involves the following steps:

- Remove roots from the pipe and flush debris from the pipe.

- Set up a sewer bypass system, if necessary, to re-route wastewater to other nearby pipes during the pipe lining process.

- Set up and run a vactor truck, or sewer vacuum, to keep the pipe free of debris and water during pipe lining process.

- Insert liner into the sewer pipe from the surface through a manhole.

- Expose the liner to heat or ultraviolet light to cure, or harden, the liner inside the pipe.

- Open and reinstate sewer service lateral connections that were covered by the pipe lining.

- Remove the bypass system, if any.

- Conduct quality control inspections.

Limit Water and Sewer Use During CIPP

Residents whose sewer pipes are going to be lined with CIPP will be asked to limit their water and sewage use during the CIPP lining process:

- Avoid using appliances that use large amounts of water—like showers, baths, washing machines, and dishwashers.

- Turn off all sump pumps connected to the sewer line.

- Limit flushing toilets.

- Limit running or pouring water or other liquids down the drain.

During the pipe lining process, connections to the public sewer on private property will be temporarily shut off. When lining a private sewer line, it is important to use less water to avoid water backing up into a home.

There may be a period of limited water and sewer use between one and several hours, depending on the length and width of the sewer pipes to be lined.

If residents are required to use limited water or sewer, they will be notified between 24 and 48 hours in advance. After the pipe lining process is complete and the work zone has been cleared, residents may resume normal water and sewer use.

Unpleasant Odors and How to Prevent Them

Residents may smell an odor like plastic or glue when the pipe lining process is taking place. The odor will quickly dissipate once the job is done. Liner resin contains chemicals that produce the odor. Based on the findings of an independent industrial hygienist, the levels detected are below health risk levels.

By filling floor drains and infrequently used sinks with water, you can prevent resin odors from entering your home or business. Water will collect in the bend in the drain, which is called a “P-trap,” and prevent odors from entering the sewer.

If there is already an odor of resin in a home or business, cover all basement drains and open windows to provide ventilation. If the odor persists, contact the contractor’s construction notice, or call M&B Services and leave a message with the address, project name, and name and phone number for follow-up.

We service the following neighborhoods and surrounding areas in Minneapolis and St. Paul:

Minneapolis (Calhoun Isles, Camden, Central, Uptown, Southwest, University, Nokomis, Longfellow, Near North, Powderhorn)

St. Paul (Highwood Hills, Greater East Side, West Side, Dayton’s Bluff, Payne-Phalen, North End, Frogtown, Summit-University, West 7th/Fort Road, Como Park, Hamline Midway, Saint Anthony Park, Union Park, Macalester-Groveland, Highland Park, Summit Hill, Downtown)