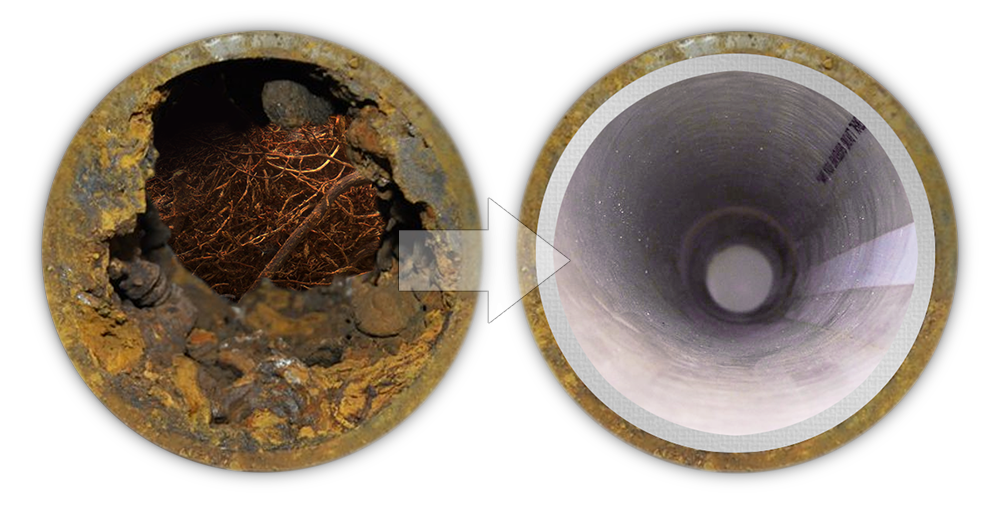

Usually, repairing of pipelines involves excavation but cured-in-place pipe or CIPP is a method where existing pipelines can be repaired by plumbers without any excavation. In this process, a resin-situated tube is inserted into the damaged pipe. Usually, a hole is dug upstream by plumbers to get access to the pipe.

Air or water pressure is then used to feed the tube into the pipe. Once the tube reaches the desired place, a balloon is inflated at the desired place to keep the liner in place. This gives enough time to resin to cure. The resin becomes hard, durable and strong once it cures. All this process leads to the creation of a pipe within the pipe without any disruption to your schedule or your property.

Party coverage

The process of CIPP works great in straight pipes that have few connections. This is due to the reason that the CIPP process covers only parts of the pipe when used for vent piping and interior drains. When this process is used even on the simplest connections, the resin does not cover the fittings and it makes them vulnerable to further damage. There is another problem which is the potential buildup at the start and end of lining which might lead to corrosion at these places.

Obviously, these problems have some solutions. One solution is called reinstatement. In this process, the entire pipe is lined by the plumber and then holes are cut at places where there are connections. This process is carried very carefully by measuring the distance at which fittings are, before installation of the liner. Some plumbing experts also recommend installation of short tee connection liners to cover irregular shapes and sizes of these cutouts.

Another process which is used in such cases is called gapping. In this case, the liner is put in place by the plumber but some gaps are left at the fittings. The lining application is then started again beyond the fittings. This process helps in avoiding complications that typically happen at valves and pipe intersections. It’s a more cost-effective solution. However, it’s not a proper solution for all the potential problems. The gaps created in this process lead to creation of lips that might cause buildup or clogging inside the pipes. In case of clogging, absence of lining at the connections means the pipe remains unprotected at these places.

Problems with Small Diameter Pipes

Creating a pipe within a pipe covers very little diameter of the original pipe. Typically, 1/4 of an inch is covered by the new pipe. This is usually fine with normal pipes as the flow remains normal once the resin is in place. However, smaller diameter pipes might develop problems.

For instance, smaller pipes with a diameter between 4 to 6 inches are typically not big enough for placement of liner and balloon inflation. Similarly, older pipes tend to be too small for this process. If the entire system isn’t lined, these smaller pipes are put at risk of damage and failure in the future.

Ideally, CIPP system should only be used in places where the entire pipe system is accessible to plumbers. If full system warranty isn’t offered by the plumbing company, you should seriously reconsider use of CIPP method.

Problems Due to Pipe Grade

The effectiveness of CIPP also depends on the grade of pipe. In many cases, the structural integrity of the lateral waste line piping is lost which leads to grade malformation. It might cause the pipe to bend or sag. It is not possible to change the pipe shape by applying any type of lining.

Quality Inconsistency

If one thing that can make a huge difference when it comes to quality of the repair, it is the skill of the plumber you have hired for installing the pipeline. These skills of the plumber matters a lot when it comes to installation of cured-in-place pipe as well as trench-less epoxy linings. When CIPP solution is used for repairing an existing epoxy lining, there are some unique challenges that need to be overcome. Any failures and it can lead to huge problems in the future.

For instance, one of the problems that can happen is failure of resin to cure. If it happens, the spot where the resin hasn’t cured will need to be repaired which will add on to the cost of pipe repair. Also, the old pipe needs to be completely clean before installation of CIPP. If there is grease or corrosion on the wall, it will prevent the resin from covering it fully and that will lead to future issues.

Overall, the long-term result of your pipe repair project depends a lot on the quality of plumber you hire for that project. Some companies take shortcuts and if you hire them, you might end up spending a lot more money in the long run.